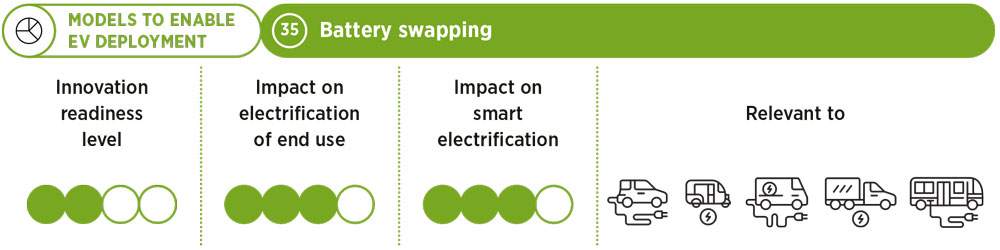

Battery swapping

Overview of the status and impact of the innovation

What

Instead of charging the battery in a vehicle, battery swapping replaces empty battery packs with fully charged packs. For swapping to work, battery packs must be easily accessible and replaceable. Swapping also is easiest when batteries are lightweight, as in electric two- and three-wheelers. For heavier vehicles, battery swapping is more complicated, requiring a mechanic’s assistance.

The battery swapping model requires the removed battery packs to be recharged. This greatly increases the number of battery packs that must be in circulation, raising the overall costs.

Why

Battery packs are the most expensive component of EVs, representing about one-third of the total cost of the vehicle, and they degrade over time. Outsourcing batteries’ maintenance and replacement can therefore reduce costs for EV drivers and owners. In some cases, it also replaces potentially long charging times with quick swaps, which could be especially useful for fleet managers. Providers, meanwhile, can realise revenues not only from swap customers, but also from the services offered to the grid using the batteries stored at swapping points.

BOX 3.28 Battery swapping for two- and three-wheelers in Taiwan and Ample, a US-based battery swapping start-up

BOX 3.29 Battery swapping pilot project for heavy trucks in China

As part of the National Energy Group’s “electric heavy truck green transportation pilot project”, two battery swapping stations, which can serve 100 heavy trucks, were built. The green electricity generated by distributed photovoltaic in this project directly provides power supply to the battery swapping stations. Vehicles can realise automatic battery swapping within 3-5 minutes. The project is expected to reduce the regional transport logistics cost by 5-10%, cause annual average carbon dioxide emission reductions of 137 000 tons and lead to a decrease of 1 730 tons in emissions.

Related kits

Power to mobility innovations

Innovations (35)

-

Technology and infrastructure

- 1 EV model evolution

- 2 EV batteries

- 3 Battery recycling technology

- 4 Diversity and ubiquity of charging points

- 5 Wireless charging

- 6 Overhead chargings

- 7 Portable charging stations

- 8 V2G systems

- 9 Digitalisation for energy management and smart charging

- 10 Blockchain-enabled transactions

- 11 Smart distribution transformers

- 12 Smart meters and submeters

-

Market design and regulation

-

System planning and operation

- 20 Cross-sectoral co-operation and Integrated planning

- 21 Including EV load in power system planning

- 22 Grid data transparency

- 23 Clean highway corridors

- 24 Operational flexibility in power systems to integrate EVs

- 25 Management of flexible EV load to integrate variable renewable energy

- 26 Management of flexible EV load to defer grid upgrades

- 27 EV as a resilience solution

-

Business models