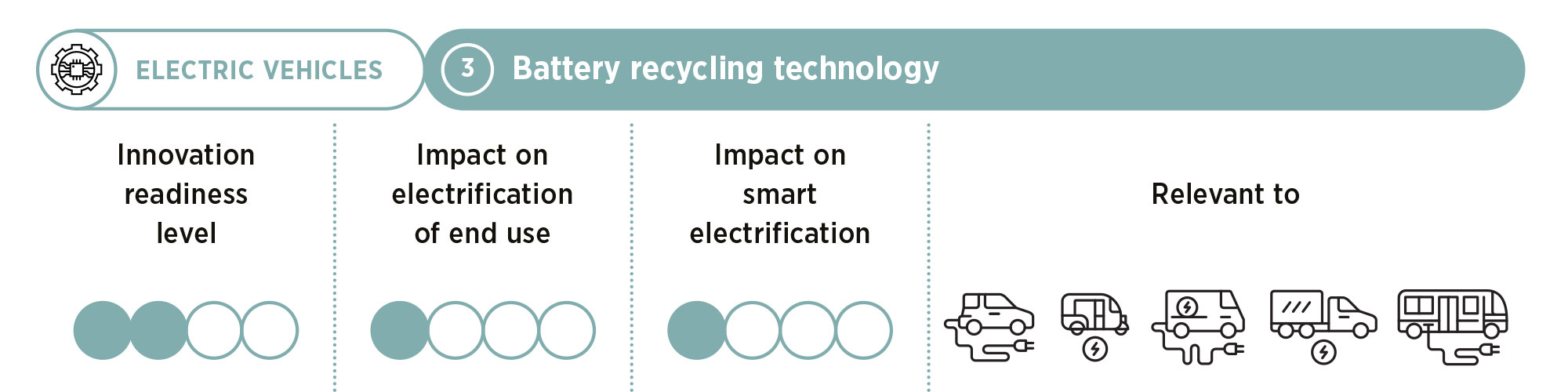

Battery recycling technology

Overview of the status and impact of the innovation

What

Batteries contain materials such as lithium, nickel, cobalt, manganese, graphite, copper and lead, the extraction and improper disposal of which carry significant environmental and health dangers (Jacoby, 2019). Currently, not all minerals are recycled due to technology pathways and economic incentives. That is why efforts are underway to address various challenges, including logistical, technical, economic and regulatory challenges, and design batteries for recycling, with a goal of achieving flexibility, scalability and efficiency in recycling. Compared with lead batteries, the complexity of lithium-ion batteries and their various chemistries makes it difficult to establish one robust recycling process for all types and make a business case for recycling. Currently used recycling methods and their combination include using high temperature or aqueous solutions to extract metals, cathode components and other materials for reuse in new batteries or other industries. Innovation is critical here since these methods will need to be flexible and adaptable to future battery chemistries.

Why

The increasing number of EVs could well aggravate environmental damage from mining and battery waste unless recycling programmes are expanded, and various challenges are quickly and properly addressed. Governments are increasingly mandating recycling, such as the Battery Regulation in the EU, and providing government funding to innovate and scale up recycling, including lowering recycling costs, increasing recovery rates, and improving the carbon and energy footprint. Sourcing of materials through recycling is, however, not expected until mid-to-late 2030s, and by 2030, a primary recycling source will be processed scrap, recalls and discarded products (IRENA, forthcoming).

BOX 3.3 Innovation areas in battery recycling technology

The recycling of battery materials has attracted attention worldwide. Recovery rates of nickel and cobalt are about 95% in recycling plants, while that of lithium, manganese and graphite (with impurities) has reached around 95%, and the recovery rate is up to 99% in laboratory testing. Improving and scaling up the recycling of all materials will not only help to avoid the adverse environmental, health and social impacts associated with mining and processing, but will also minimise dependency on material imports, unlock new domestic value streams and job opportunities, and may reduce the costs of batteries (IRENA, forthcoming).

Related kits

Power to mobility innovations

Innovations (35)

-

Technology and infrastructure

- 1 EV model evolution

- 2 EV batteries

- 3 Battery recycling technology

- 4 Diversity and ubiquity of charging points

- 5 Wireless charging

- 6 Overhead chargings

- 7 Portable charging stations

- 8 V2G systems

- 9 Digitalisation for energy management and smart charging

- 10 Blockchain-enabled transactions

- 11 Smart distribution transformers

- 12 Smart meters and submeters

-

Market design and regulation

-

System planning and operation

- 20 Cross-sectoral co-operation and Integrated planning

- 21 Including EV load in power system planning

- 22 Grid data transparency

- 23 Clean highway corridors

- 24 Operational flexibility in power systems to integrate EVs

- 25 Management of flexible EV load to integrate variable renewable energy

- 26 Management of flexible EV load to defer grid upgrades

- 27 EV as a resilience solution

-

Business models