EV batteries

Overview of the status and impact of the innovation

What

Batteries for new EVs already provide good ranges, with the best-performing models offering 800 kilometres (km), and some batteries can be charged in an hour. At the same time, prices have dropped dramatically, from USD 1 200/kWh in 2010 for Li-ion batteries to USD 132/kWh in 2021 (BloombergNEF, 2021b). Battery improvements are a complex undertaking involving several tradeoffs (Box 3.2), but the top priority is to continue cutting cost, increasing range and shortening charging cycles. That said, range becomes less important if batteries can be correctly sized for the intended uses and charging is readily available. Automakers should consider warrantying the number of cycles, not just the kilometres covered, so that the batteries of passenger and fleet vehicles can more readily be used in vehicle to grid (V2G). Proper accounting of battery health and cycles will also facilitate second uses for batteries after the original vehicles are no longer on the road.

An emerging technology concern for EV batteries is the availability of critical materials used to make the batteries, such as cobalt. Viable cobalt-free battery technologies exist – one is lithium iron phosphate – but their energy density needs to be improved.

Why

Innovation in battery technology will improve performance, increase range and battery lifetimes, and stimulate further adoption of EVs.

BOX 3.2 Innovation areas in EV battery technology

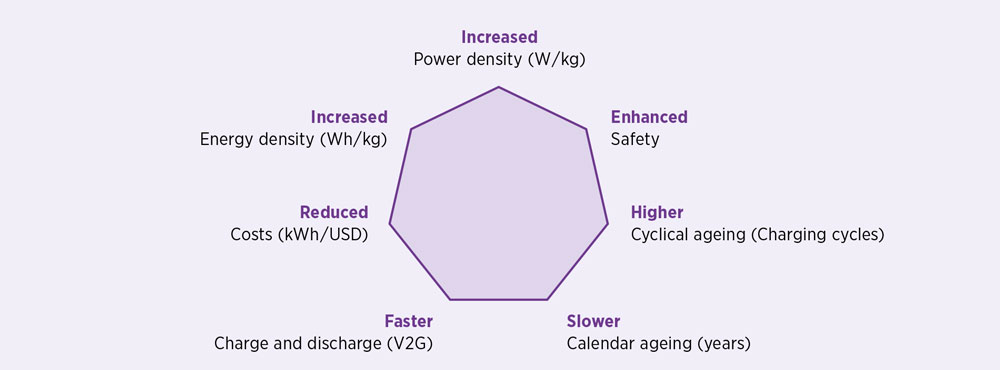

Research efforts are aimed at improving at least seven battery performance metrics (Figure 3.2), but there are complex trade-offs among those properties, and improving one criterion typically results in the deterioration of at least one other.

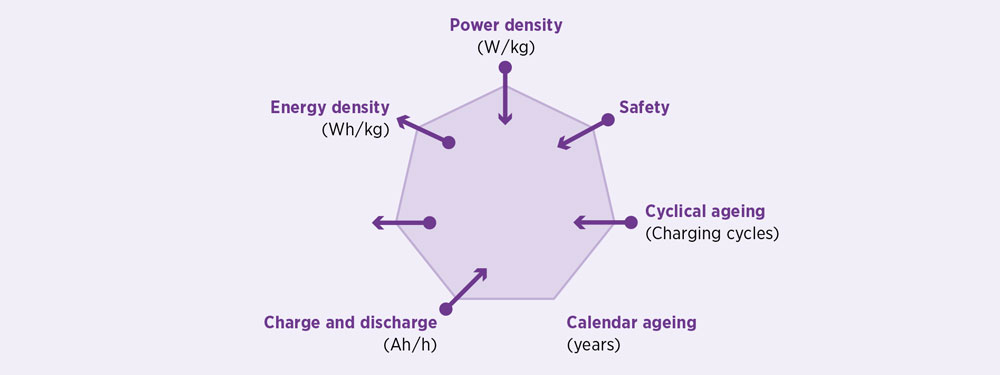

FIGURE 3.3 The battery performance dilemma

In general, the focus has mostly been on improving energy density and safety while reducing costs, and to a lesser extent on increasing charging cycles . But further improvements are necessary in cyclical ageing, power density and fast-charging capability as well. These depend highly on the battery cell type, how the cells are packed together and how charging is managed. Figure 3.3 shows how an innovation that improves energy density and cost comes at the expense of power density, security and cyclical ageing.

FIGURE 3.4 Example of battery innovation

The CTC (cell to chassis) grouping technology developed by CATL improves the volume utilisation of battery packs through highly integrated structural design. In terms of material innovation, CATL released the first generation of sodium-ion batteries, with energy density of up to 160 Wh/kilo gramme (kg) of a single cell, which can be applied to various transportation electrification scenarios, especially in cold regions, and can flexibly adapt to all scenarios in the field of energy storage. Industrial application of sodium-ion batteries is expected to be demonstrated in 2023, which can reduce the demand for lithium resources.

Related kits

Power to mobility innovations

Innovations (35)

-

Technology and infrastructure

- 1 EV model evolution

- 2 EV batteries

- 3 Battery recycling technology

- 4 Diversity and ubiquity of charging points

- 5 Wireless charging

- 6 Overhead chargings

- 7 Portable charging stations

- 8 V2G systems

- 9 Digitalisation for energy management and smart charging

- 10 Blockchain-enabled transactions

- 11 Smart distribution transformers

- 12 Smart meters and submeters

-

Market design and regulation

-

System planning and operation

- 20 Cross-sectoral co-operation and Integrated planning

- 21 Including EV load in power system planning

- 22 Grid data transparency

- 23 Clean highway corridors

- 24 Operational flexibility in power systems to integrate EVs

- 25 Management of flexible EV load to integrate variable renewable energy

- 26 Management of flexible EV load to defer grid upgrades

- 27 EV as a resilience solution

-

Business models