Hydrogen-ready equipment

Overview of the status and impact of the innovation

What

Hydrogen-ready equipment refers to energy-related infrastructure that can cope with hydrogen, such as meters, junctions, recompressing facilities and pipelines. Liquefied natural gas (LNG) terminals are good examples of infrastructure ready to host or become green hydrogen hubs. The existing infrastructure cannot cope with pure hydrogen due to the tiny size of hydrogen molecules (in the case of storage tanks), and its potential embrittlement capacity that weakens metal structures and causes leaks. However, LNG terminals can move hydrogen in the form of ammonia. According to some estimates, the cost of turning LNG terminals into ammonia ones is 15% of the cost of building a completely new facility. Yet, if the final goal is to produce pure hydrogen, the energy cost of getting this pure hydrogen from ammonia is high, which implies a large amount of clean power to guarantee green hydrogen as an output.

Why

At infant stages of a hydrogen economy, hydrogen-ready equipment can serve as a transitional technology or proof-of-concept for the integration of a small amount of hydrogen in the energy system. Adapting current infrastructure to the use of hydrogen can bring costs down and bring new innovations (technological and business oriented) into the market, thus serving to trigger the hydrogen economy.

BOX 9.2 Hydrogen backbone projects in the Netherlands

The country’s first project to heat homes with 100% green hydrogen began in June 2019 in Rozenburg, Rotterdam. The project is a joint initiative of network operator Stedin, the municipality of Rotterdam, DNV GL, Remeha, Bekaert Heating and the housing co-operative Ressort Wonen. The hydrogen will be produced locally with a greenelectricity- powered electrolyser and transported over an existing gas pipeline to the apartment complex’s boiler. Stedin also plans a similar project that will supply 100% hydrogen to 550 homes over a repurposed natural gas grid in the southern Netherlands by 2025. The hydrogen will be produced by eight anion exchange membrane electrolysers supplied by Enapter.

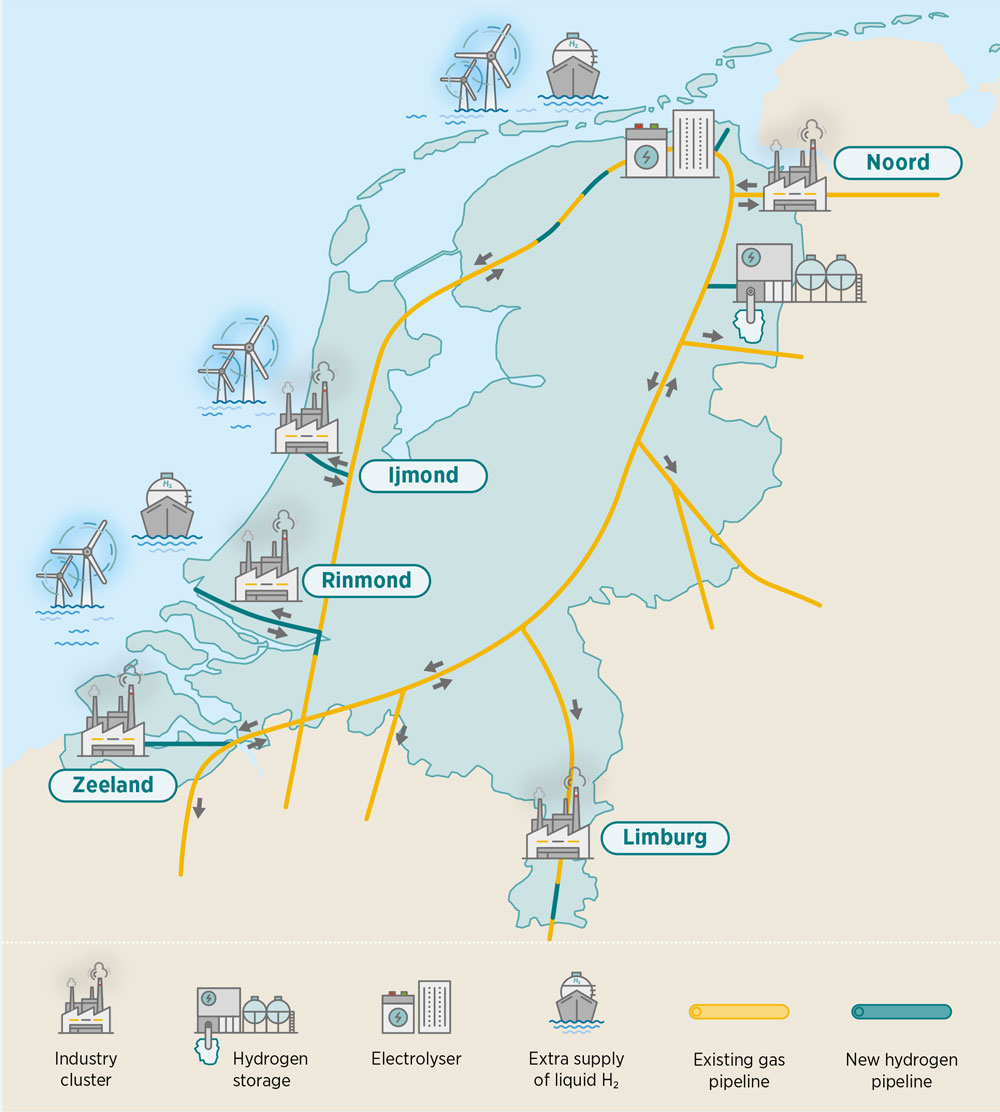

In addition, Gasunie, the gas transmission system operator in the Netherlands, is planning to build a national hydrogen network that will connect five industrial clusters to hydrogen storage facilities (Figure 9.2). Approximately 85% of the network will be repurposed natural gas pipelines (Gasunie, 2022).

FIGURE 9.2 Plans for the hydrogen backbone project in the Netherlands for 2030

Related kits

Power to hydrogen innovations

Innovations (30)

-

Technology and infrastructure

- 1 Pressurised alkaline electrolysers

- 2 Polymer electrolyte membrane electrolysers

- 3 Solid oxide electrolyser cell electrolysers

- 4 Anion exchange membrane electrolysers

- 5 Compressed hydrogen storage

- 6 Liquefied hydrogen storage

- 7 Hydrogen-ready equipment

- 8 Digital backbone for green hydrogen production

- 9 Hydrogen leakage detection

-

Market design and regulation

- 10 Additionality principle

- 11 Renewable power purchase agreements for green hydrogen

- 12 Cost-reflective electricity tariffs

- 13 Electrolysers as grid service providers

- 14 Certificates

- 15 Hydrogen purchase agreements

- 16 Carbon contracts for difference

- 17 Regulatory framework for hydrogen network

- 18 Streamline permitting for hydrogen projects

- 19 Quality infrastructure for green hydrogen

- 20 Regulatory sandboxes

-

System planning and operation

-

Business models