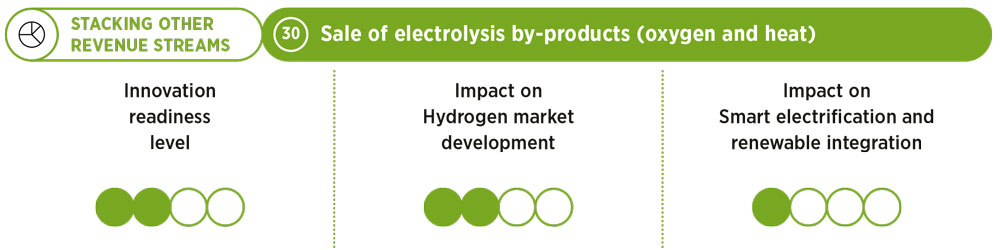

Sale of electrolysis by products (oxygen and heat)

Overview of the status and impact of the innovation

What

In addition to producing hydrogen, the electrolysis process also produces pure oxygen and low-temperature heat. Electrolysers could sell both these by-products to gain additional revenue streams. The oxygen market is already well established, with many uses in industry, such as blast furnaces and glass melting. However, electrolysers selling oxygen would face strong competition from air separation units that produce oxygen at a very low price. Meanwhile, the lowtemperature excess heat could be used for applications such as district heating or direct process heat in industry.

Why

Selling by-products has the potential to improve the energy and economic efficiency of power-to-hydrogen applications, strengthening the business case for electrolysers. This business model should be especially considered when developing large-scale clean hydrogen projects.

BOX 9.24 HySynergy: Excess heat for district heating in Denmark

The HySynergy project, which is located next to Shell’s Fredericia refinery in Denmark, will produce and store hydrogen in large quantities to supply the refinery and create a competitive supply of green hydrogen for use in heavy-duty transport. The project will begin with a 20 MW electrolyser, and then a 300 MW electrolyser and a 1 GW unit will be added. These electrolysers will also send surplus heat to TVIS (a utility located in the centre of Denmark), which uses a regional heating network to provide heat to 180 000 citizens in four major cities. The project will also explore the use of its oxygen by-product for carbon capture processes.

BOX 9.25 Power-to-gas-to-heat facility in Lahti, Finland

Nordic Ren-Gas developed a power-to-gas plant in Lahti for the production of synthetic methane, green hydrogen and district heating from the excess heat of the process. The location of the plant enables integration with a nearby district heating system.

Ren-Gas’s objective is to build a production network that will deliver 20% of the fuel needed by the heavy road transport sector and 8% of the district heating needs by 2030 in Finland. This translates into the replacement of 2.5 TWh of district heating produced from fossil fuels. The overall project expects to avoid 1.5 million of CO2 per year.

Related kits

Power to hydrogen innovations

Innovations (30)

-

Technology and infrastructure

- 1 Pressurised alkaline electrolysers

- 2 Polymer electrolyte membrane electrolysers

- 3 Solid oxide electrolyser cell electrolysers

- 4 Anion exchange membrane electrolysers

- 5 Compressed hydrogen storage

- 6 Liquefied hydrogen storage

- 7 Hydrogen-ready equipment

- 8 Digital backbone for green hydrogen production

- 9 Hydrogen leakage detection

-

Market design and regulation

- 10 Additionality principle

- 11 Renewable power purchase agreements for green hydrogen

- 12 Cost-reflective electricity tariffs

- 13 Electrolysers as grid service providers

- 14 Certificates

- 15 Hydrogen purchase agreements

- 16 Carbon contracts for difference

- 17 Regulatory framework for hydrogen network

- 18 Streamline permitting for hydrogen projects

- 19 Quality infrastructure for green hydrogen

- 20 Regulatory sandboxes

-

System planning and operation

-

Business models