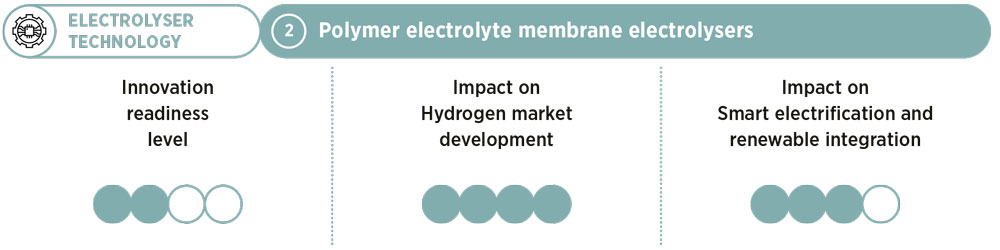

Polymer electrolyte membrane electrolysers

Overview of the status and impact of the innovation

What

PEM electrolysers use cells with a solid polymer electrolyte. The cells typically operate at temperatures between 50°C and 80°C and at pressures between 20 and 40 bar. The benefit of PEM electrolysers lies in their more compact and simple system design, compared with ALK electrolysers, and their ability to function with higher current densities, allowing a smaller carbon footprint. They can also be ramped up and down (and completely stopped and started up) much faster than even pressurised ALK electrolysers (see Table 9.3). However, PEM electrolysers do require titaniumbased materials, noble metal catalysts and protective coatings because of their harsh oxidative environment and high voltages. They are thus more expensive than ALK electrolysers (Table 9.3). Research efforts are now focusing on reducing the use of noble materials, such as iridium, to lower the costs of PEM electrolysers. The objective is to reduce the capital costs of a minimum 10 MW system from about USD 700-1 400/kW in 2020, to less than USD 200/kW by 2050.

Why

PEM electrolysers can ramp up or down in seconds, providing tremendous flexibility to power systems. This facilitates greater integration of renewable generation, increases the power grid’s resilience and allows the electrolysers to receive additional revenues from providing grid-balancing services – thus improving the overall economics of a PEM electrolyser facility.

Related kits

Power to hydrogen innovations

Innovations (30)

-

Technology and infrastructure

- 1 Pressurised alkaline electrolysers

- 2 Polymer electrolyte membrane electrolysers

- 3 Solid oxide electrolyser cell electrolysers

- 4 Anion exchange membrane electrolysers

- 5 Compressed hydrogen storage

- 6 Liquefied hydrogen storage

- 7 Hydrogen-ready equipment

- 8 Digital backbone for green hydrogen production

- 9 Hydrogen leakage detection

-

Market design and regulation

- 10 Additionality principle

- 11 Renewable power purchase agreements for green hydrogen

- 12 Cost-reflective electricity tariffs

- 13 Electrolysers as grid service providers

- 14 Certificates

- 15 Hydrogen purchase agreements

- 16 Carbon contracts for difference

- 17 Regulatory framework for hydrogen network

- 18 Streamline permitting for hydrogen projects

- 19 Quality infrastructure for green hydrogen

- 20 Regulatory sandboxes

-

System planning and operation

-

Business models