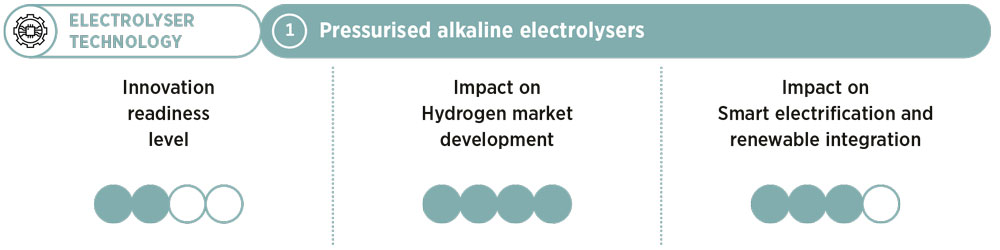

Pressurised alkaline electrolysers

Overview of the status and impact of the innovation

What

ALK electrolysers are the most mature technology and are already at the commercial stage. They have a simple stack system design and are relatively easy to manufacture. Their capital costs are lower than those of other electrolyser technologies (see Table 9.3). While ALK electrolysers can operate at either atmospheric pressures or high pressures (up to 30 bar), high-pressure electrolysers can be ramped up and down much faster (in less than a minute) than those operating at atmospheric pressure, which take several minutes to ramp up or down. High-pressure ALKs are therefore better at following fluctuations in wind and solar generation.

Why

Given that pressurised ALK electrolysers can rapidly follow fluctuations in wind and solar production, its smart integration would facilitate the integration of variable renewable sources. ALK electrolysers also have lower investment costs than other technologies, and have been certified to provide primary reserves to the power system (IRENA, 2020c).

Related kits

Power to hydrogen innovations

Innovations (30)

-

Technology and infrastructure

- 1 Pressurised alkaline electrolysers

- 2 Polymer electrolyte membrane electrolysers

- 3 Solid oxide electrolyser cell electrolysers

- 4 Anion exchange membrane electrolysers

- 5 Compressed hydrogen storage

- 6 Liquefied hydrogen storage

- 7 Hydrogen-ready equipment

- 8 Digital backbone for green hydrogen production

- 9 Hydrogen leakage detection

-

Market design and regulation

- 10 Additionality principle

- 11 Renewable power purchase agreements for green hydrogen

- 12 Cost-reflective electricity tariffs

- 13 Electrolysers as grid service providers

- 14 Certificates

- 15 Hydrogen purchase agreements

- 16 Carbon contracts for difference

- 17 Regulatory framework for hydrogen network

- 18 Streamline permitting for hydrogen projects

- 19 Quality infrastructure for green hydrogen

- 20 Regulatory sandboxes

-

System planning and operation

-

Business models