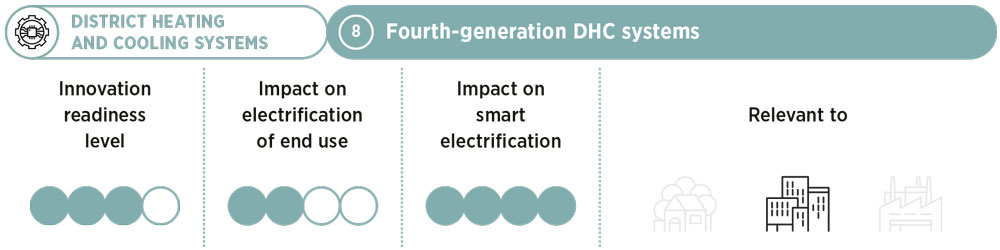

Fourth-generation DHC systems

Overview of the status and impact of the innovation

What

DHC systems date back to the late 19th century but have undergone considerable changes and improvements since then. Many of the newest DHC systems are known as “fourth-generation” systems. They work at lower temperatures than the earlier generation systems, making them more efficient and lowering the related supply costs, because they can use lower-quality (lowertemperature) heat sources.

For a district heating system to be classified as a fourth-generation (4GDH) system, it must use smart integration to maximise the overall efficiency as well as the use of locally available renewable energy sources. A key feature of 4GDH systems is that they supply heat or cooling at temperatures as close as possible to the actual temperatures required by end users – a maximum of 60-70°C. Such relatively low supply temperatures (for heating) reduce losses in the district heating system and facilitate greater integration of waste heat sources (e.g. excess heat from data centres) than is possible using third-generation systems. 4GDH systems also use large-scale heat pumps of much higher efficiency to further exploit low-temperature waste heat sources or ambient heat. They may also use heat or cold storage to support the smart operation of heat pumps (Lund et al., 2021).

Why

4GDH systems add major benefits; for example, they lead to low overall energy consumption and add flexibility to the power system. Compared with earlier generation systems, they have reduced grid losses by 6%, primary energy consumption by 4.5% and total costs by 2.7%.

BOX 6.8 Districlima, Barcelona, Spain

One of the largest district heating and cooling systems in Spain is in the city of Barcelona. Now a fourth-generation system, it continues to expand across the city. The system has two primary production plants with a total cooling capacity of 113 MW and heating capacity of 79 MW. It also has a 40 MWh water storage tank and a 120 MWh ice storage tank. The system supplies heating and cooling to a 20.2 km network.

Most of the heating and part of the cooling are produced using the steam generated by a nearby urban waste incinerator. Cold generation is assisted by industrial electric chillers cooled with seawater.

Storage systems allow the city to supply heating and cooling during periods of high demand and reduce costs by storing energy when demand is low. The network expansion has resulted in the growth of annual carbon dioxide emissions reductions from 10 654 tonnes in 2009 to 29 792 tonnes in 2019.

Related kits

Power to heat and cooling innovations

Innovations (35)

-

Technology and infrastructure

- 1 Low-temperature heat pumps

- 2 Hybrid heat pumps

- 3 High-temperature heat pumps

- 4 Waste heat-to-power technologies

- 5 High-temperature electricity-based applications for industry

- 6 Low-temperature thermal energy storage

- 7 Medium- and high-temperature thermal energy storage

- 8 Fourth-generation DHC systems

- 9 Fifth-generation DHC systems

- 10 Internet of Things for smart electrification

- 11 Artificial intelligence for forecasting heating and cooling demands

- 12 Blockchain for enabling transactions

- 13 Digitalisation as a flexibility enabler

-

Market design and regulation

- 14 Dynamic tariffs

- 15 Flexible power purchase agreement

- 16 Flexible power purchase agreement

- 17 Standards and certification for improved predictability of heat pump operation

- 18 Energy efficiency programmes for buildings and industry

- 19 Building codes for power-to-heat solutions

- 20 Streamlining permitting procedures for thermal infrastructure

-

System planning and operation

-

Business models

- 28 Aggregators

- 29 Distributed energy resources for heating and cooling demands

- 30 Heating and cooling as a service

- 31 Waste heat recovery from data centres

- 32 Eco-industrial parks and waste heat recovery from industrial processes

- 33 Circular energy flows in cities – booster heat pumps

- 34 Community-owned district heating and cooling

- 35 Community-owned power-to-heat assets