Hydrogen

About

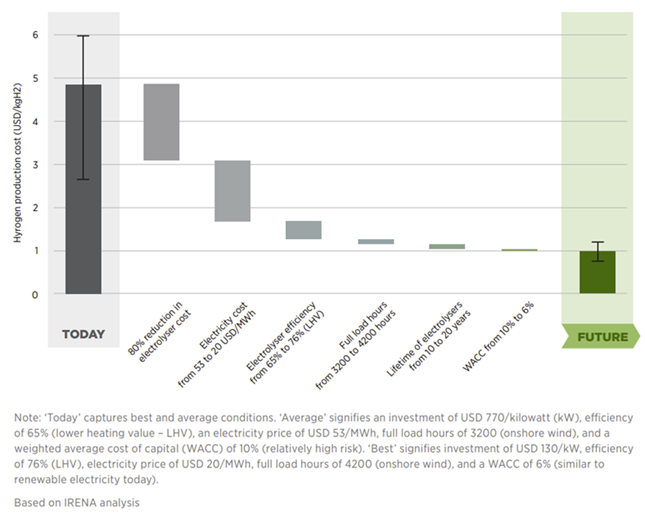

The largest cost driver in producing renewable hydrogen is the electricity price. Renewable electricity has already become the cheapest source in many countries around the globe and its costs should continue declining over the coming years. Yet, this alone will not be enough to make green hydrogen production cost-competitive.

The next major hurdle in achieving low-cost green hydrogen is to reduce the investment cost of the electrolyser. A reduction of up to 80% in the investment cost of the electrolyser can be achieved through a combination of four strategies:

- Innovation will be crucial to reducing cost by improving the performance of the electrolyser, specifically for improved efficiency and durability and simpler design. Technologies that are free from rare earth materials, or which have a large reduction from today’s levels, will be key to scaling up electrolysers to the multi-gigawatt scale.

- Increase the electrolyser size and reducing the cost contribution from the balance of plant and auxiliary equipment. Cost is not the only driver for module size – the specific application will have a large role in system cost.

- Mass-manufacture of the electrolyser core (the “stacks”) will drive cost down. Achieving a production scale of around 1 GW/yr could allow (semi-)automated manufacturing and a reduction in the fixed costs per unit manufactured.

- Standardising the design, optimising the supply chain, replicating installation, and learning from best practices in deployment are all promising methods of reducing cost.

Applying these strategies, locations in the world that achieve a renewable electricity cost of USD 20/MWh or below could produce green hydrogen at less than USD 2.5/kgH2 in the coming five to ten years, and at less than USD 1/kgH2 before 2040 in a scenario with an ambitious electrolyser deployment (see Figure 4).

The electrolyser stack can respond fast enough to follow variable renewable electricity output. The limitation in response usually lies in the auxiliary equipment, such as hydrogen compression and processing. Variability can be attenuated for downstream by the inclusion of intermediate hydrogen storage.

Levels of water use for green hydrogen production would be relatively small compared to current usage for thermal generation. Even in areas subject to water stress, as long as there is access to sea water, desalination plants could be used with limited impact on hydrogen production cost.