Transportation costs

Contact us

Send a messageAbout

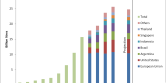

Conventional biofuels derived essentially from food-based feedstocks (e.g. oil seed crops) have seen their production costs increase in recent years due to high food prices. Advanced biodiesels from lignocellulosic feedstocks are just beginning to be produced by first-of-a-kind plants at commercial production scales. In 2012, 24 billion litres of biodiesel were produced globally, with virtually all of this from conventional processes.

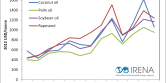

Conventional biodiesel production costs are dominated by feedstock costs. Between 2005 and 2012 feedstock costs for biodiesel increased by 87% for soybean and 49% for rapeseed oil, with average production costs estimated at USD 1.3/litre of diesel equivalent in 2012. Biodiesel produced from palm oil in Malaysia and Indonesia was estimated to have lower production costs, at around USD 1/litre.

Advanced biodiesel production methods are still at an early stage of commercialisation. However, with around 15 advanced biofuel plants planned to come online within the next few years, the emerging cost data suggest the outlook to 2020 is positive, given the high cost reduction potential. IRENA analysis estimates that increased investment in R&D and additional experience in commercial-scale projects could reduce production costs from USD 0.8–1.3 per litre of diesel equivalent (as of 2017) to USD 0.6–1.1 by 2020, making advanced biodiesel technologies competitive with fossil fuels. However, this assumes that some of the technology pathways being initially explored can quickly prove their reliability at commercial scales.

Past Events

More events-

13-15 January 2023 Abu Dhabi, United Arab Emirates

Thirteenth Session of the IRENA Assembly