Sustainable Flight with Biofuels

Newsletter

So what can be done? What’s the environmentally responsible solution for aviation, and how can emissions be reduced, short of removing planes from the skies?

Bio-flying

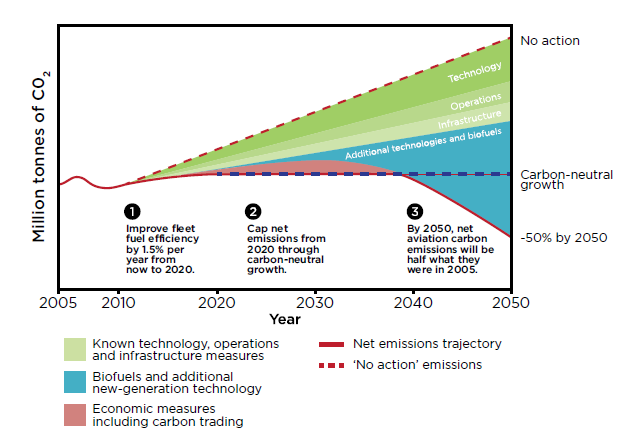

Technology development has meant that plane designs are improving and engines are getting more efficient. There’s a host of ongoing efficiency changes in all aspects of air travel (improved fuel efficiency in new aircraft, aircraft modifications, airport restructuring, and optimised navigational systems) that are helping to reduce CO2 emissions by about 1.5% annually. But because aircraft have a long life span and are very expensive, airlines typically want to use them as long as possible before replacing them, so rolling out these changes and meeting 2020 and 2050 emission reduction goals requires more drastic changes.

Source: Air Transport Action Group

“To achieve significant reduction and go beyond carbon neutral growth, the aviation sector will have to shift to the use of renewable and sustainable fuels, such as biofuels developed for jet aircraft,” says Dolf Gielen, Director of the IRENA Innovation and Technology Centre.

“In the industry, biofuels for jet aircraft are known as ‘biojet’ or ‘biojet fuels’. They’re the only real option for achieving significant reductions in aviation emissions by 2050. They won’t even require plane engine modification,” explains Deger Saygin an IRENA Programme Officer.

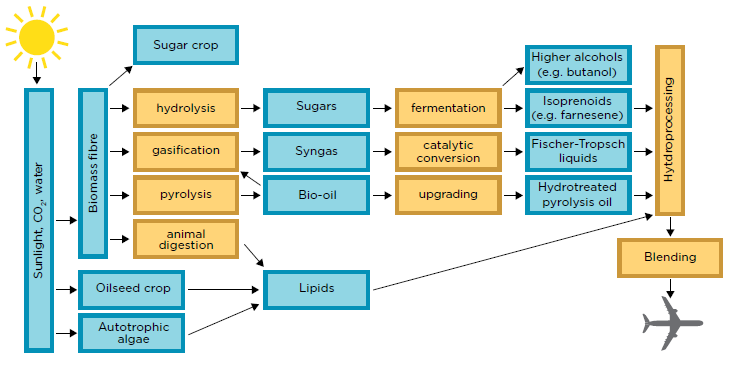

Biojet fuels exists today, but current production is limited, comprising less than than 0.1% of global total jet fuel consumption. Today’s biojet fuels, ‘conventional biojet’, are derived from crops, and ‘advanced bio-jet’ — advanced liquid biofuels based on lignocellulosic biomass or algal feedstocks — will open the market to a larger variety of feedstock options and economic opportunities in the supply chain.

The aviation sector is already anticipating this transition and projects are underway to develop the next generation of advanced bio-jet. Though creating bio-jet biomass through gasification and subsequently through the Fischer-Tropsch (FT) conversion (a method that uses municipal solid waste or woody biomass as feedstock) is not yet commercial, two facilities have been planned. FT is but one of the four pathways certified for production of biofuels, the others being: alcohol to jet, based on isobutanol; synthesised iso-paraffinic fuels; and hydroprocessing esters and fatty acids.

What’s holding biofuels back?

While biojet is already in use, it only makes up a fraction of a plane's fuel and only on a tiny percentage of flights. The high cost of production is one of the main barriers to stopping greater biojet adoption, as fuel can account for as much as 30% of an airline’s total operating expense.

“Bridging the price gap between biojet and conventional fossil-based jet fuels can be achieved with the support of specific policies,” Francisco Boshell, an IRENA analyst, explains. “Considering implementing mandates to foster biojet demand, and supply-chain policies to support its commercialisation, could see costs drops and uptake increase. We’re already seeing it happen.”

The Netherlands and the U.S. have implemented policies that promote biojet production and use, and Indonesia has announced a bio-jet mandate to grow biojet demand but runs a risk if its supply can’t match it. “No single policy will be able to create the perfect conditions for biojet to be commercially competitive. We need to address its competitiveness in all areas possible, if we’re serious about fully switching to biojet fuels and meeting the aviation sector’s emission reduction goals,” Boshell says.

To learn more about the aviation sector’s low-carbon potential through biofuels, check out IRENA’s newly released technology brief, Biofuels for Aviation, the first installment of a transportation series that includes Electric Vehicles, and Biogas for Road Vehicles.