2.6 Cement

Cement has been indispensable in shaping the modern world, contributing significantly to the development of infrastructure for centuries. The combination of cement and aggregates produces a strong, durable and versatile material, making it indispensable for buildings, roads, bridges and other critical infrastructure. Cement has been pivotal in advancing urbanisation and economic growth, providing the foundational support for resilient and sustainable communities globally.

Emissions and energy use

Cement is a vital material in modern construction, serving as the binding agent that holds concrete together. Cement typically makes up 10-15% of the concrete mixture by volume, with water triggering a chemical reaction called hydration, which hardens and strengthens the concrete (American Cement Association, 2024).

Cement production is a complex, multi-stage industrial process. It begins with grinding and mixing raw materials like limestone and clay, followed by heating the mixture in rotary kilns at 1400 -1500°C to produce clinker through the calcination process. The clinker is then ground with gypsum and other additives to produce cement. In its final use, cement is combined with water, sand and aggregates to make concrete (Cembureau, 2024).

Cement manufacturing is one of the most energy-intensive sectors, next to iron and steel, and chemicals, consuming approximately 12 EJ globally, which is about 3% of global energy consumption (IEA, 2023d). The cement sector also accounts for 6% of global GHG emissions, emitting 2.2 GtCO2 annually. The largest sources of emissions are the calcination process to produce clinker and the fuel combustion to generate the high temperatures required in kilns. The chemical process of calcination accounts for 53% of the total emissions of cement production, while the thermal energy use contributes to 35%. The remaining 12% of emissions come from using electricity to grind raw materials and cement and other operational processes (McKinsey & Company, 2020).

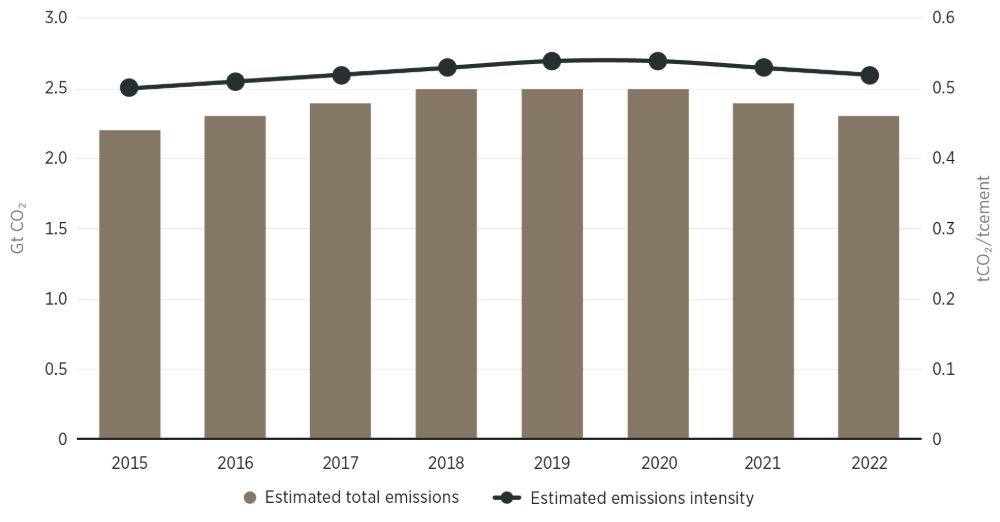

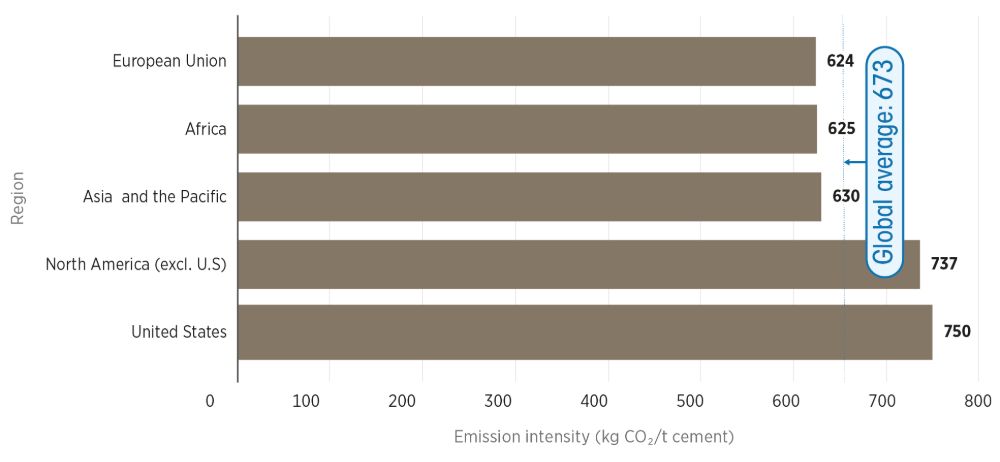

Between 2015 and 2020, total cement-related emissions rose by over 14%, from 2.2 to 2.5 GtCO2, as shown in Figure 19. However, since 2020, there has been a slight decline in CO2 emissions from the cement sector. Emission intensities also differ by region, as seen in Figure 20. The global average intensity of ordinary Portland cement is 673 kgCO2 per tonne, but disparities in energy sources and clinker-to-cement ratios result in higher intensities in regions like North America compared with Africa and Europe. For example, the average clinker-to-cement ratio in the United States is 0.88, while the world average is 0.71 (IEA, 2024a; WRI, 2024).

Figure 19: Global emissions trend for cement sector

Figure 20: Global emission intensity of ordinary Portland cement

Decarbonisation pathways

With urbanisation and infrastructure demands surging, annual global concrete production is expected to rise from the current 4.9 billion tonnes to 7 billion tonnes by 2050 (GCCA, 2024). The cement sector plays a pivotal role in global construction, and the sector faces an urgent imperative to cut carbon emissions and achieve net zero by 2050. Achieving this goal necessitates a holistic approach that targets both embodied and operational carbon, given the sector’s substantial contribution to GHG emissions. No single solution can sufficiently reduce emissions to near zero; instead, full decarbonisation requires addressing the entire life cycle of cement through a combination of strategies. These strategies include optimising concrete use, reducing emissions from production processes, and implementing innovative solutions to manage residual emissions.

Reducing the demand for cement can be achieved through improved structural design and the use of alternative materials. High-strength concrete, modular designs and lightweight construction have proven effective in lowering material consumption (Mission Possible Partnership, 2023). For example, structural optimisation projects in Germany have demonstrated a 25% reduction in material use without compromising structural integrity (IRENA, 2020). A shift towards circularity within the cement sector can significantly reduce its environmental footprint. By designing structures for deconstruction and recovering and reusing materials from end-of-life products, the industry can close the loop on material use.

Supplementary cementitious materials (SCMs), such as fly ash, blast furnace slag and naturally occurring pozzolans, not only significantly cut emissions linked to calcination but also enhance the durability of the resulting concrete. For instance, Dalmia Cement in India has achieved over 70% clinker replacement in its production processes using SCMs (GCCA, 2024). However, the availability of these materials is usually regionally constrained and subject to the decarbonisation of other sectors, such as steel and coal power. In Europe, the clinker-to-cement ratio was 77% in 2021, and it was estimated that globally the ratio is 71% (Cembureau, 2024; IEA, 2024a; WEF, 2024). SCMs are used as partial substitutes within the traditional Portland cement system, but alternative cement chemistries such as geopolymers, calcium sulfo-aluminate cements, and magnesium-based binders rely on fundamentally different chemical reactions and binder systems that do not require Portland clinker at all. These alternatives are already demonstrating commercial viability in niche applications but require significant research and development to scale globally.

Reducing energy-related emissions in cement production requires an urgent shift towards electrification and renewable energy integration. Electrification efforts are gaining traction globally, with electric cement kilns being explored as a promising decarbonisation technology. Among electrification pathways, plasma heating, radiative heating and electric arc heating technologies are being piloted for their ability to rapidly deliver the ultra-high temperatures needed for clinker formation. Innovations like Coolbrook’s RotoDynamic Heater technology are leading the way. The RotoDynamic Heater uses a high-speed electrically driven rotor to transfer energy directly to process gas, generating intense heat. It achieves the high temperatures required for cement production – around 1 700°C – using only electricity. When powered by renewable energy sources such as wind or solar, this innovation eliminates CO2 emissions from process heating and represents a significant breakthrough in decarbonising cement production (CoolBrook, 2024). However, electrification at scale remains constrained by high capital investment needs and regulatory bottlenecks for grid expansion. Moreover, the infrastructure to support high-voltage electric kilns is not yet widespread, and retrofitting existing plants can be technically and economically challenging (Cembureau, 2024; The Breakthrough Agenda Report, 2023).

The use of alternative fuels, such as biomass, refuse-derived fuel, and biogas, plays a critical role in decarbonising cement production. Europe has made significant efforts on this front, with several countries achieving substitution rates of over 40% and some plants exceeding 70% alternative fuel use (Cembureau, 2024). According to GNR data, the leading cement companies increased their use of alternative fuels from 19.1% in 2019 to 22.7% in 2022 (GCCA, 2019). In Honduras, refuse waste is diverted from landfills for sustainable use in kilns, while India has made significant progress in co-processing agricultural waste, reducing reliance on coal (GCCA, 2024). However, scaling up biomass poses a few challenges. Biomass, compared to conventional fossil fuels, often has lower calorific value, higher moisture content and variable ash characteristics, which can reduce combustion efficiency, which also affects clinker quality. In some cases, biomass co-firing can reduce clinker output and increase production costs, especially when combined with CO2 capture and storage (CCS) technologies (IRENA, 2020). Biomass supply chains are still not fully mature, with high preprocessing and transport costs. Competing demands from other sectors also put a strain on the reliability of the feedstock. Some policy-related hurdles include inconsistent waste classification and regulatory inefficiencies in emission reporting and co-processing (Cembureau, 2024).

To tackle residual emissions – primarily the process emissions from the calcination of limestone that cannot be eliminated by energy efficiency measures or with the use of renewable energy – carbon capture technologies are indispensable. The LEILAC (Low Emissions Intensity Lime and Cement) project in Europe captures CO2 directly from limestone, showcasing scalable potential. Carbon mineralisation processes, like those developed by CarbonCure, allow captured CO2 to be integrated into concrete products, enhancing strength while permanently storing emissions (GCCA, 2024).

Switching to sustainably sourced biomass to supply the heat for cement kilns and applying CCUS to emissions from the biomass-firing process (also known as bioenergy with carbon capture and storage/utilisation, or BECCS/U) could, in principle, result in negative emissions. These negative emissions represent carbon removals, as biogenic CO2 is captured and permanently stored, in contrast to conventional CCS, which primarily mitigates fossil-based process emissions. BECCS/U applications in the cement industry are still mostly at the research and development stage. Depending on the technology, the cost of BECCS in cement ranges between USD 65 and USD 116 per tonne of CO2 removed, with oxy-fuel combustion and calcium looping offering most cost-effective and energy-efficient options compared with amine-based scrubbing (IRENA, 2020, 2021c).

For conventional CCS retrofits without biomass, cost estimates for post-combustion capture in cement plants generally range from USD 60 to USD 120 per tonne of CO2, depending on the flue gas CO2 concentration, the plant configuration and the scale (Global CCS Institute, 2022; IRENA, 2021c). Retrofitting existing plants with CCS is technically feasible, particularly using post-combustion capture, though capital costs can exceed USD 2 500 per tonne of annual CO2 capture, as demonstrated by the Norcem Brevik project (IRENA, 2021c). Importantly, carbon capture becomes more energy and cost efficient at higher CO2 concentrations; electrified kiln designs or biomass co-firing can raise CO2 purity in flue gas, thereby reducing capture costs and improving performance.

Figure 21: Summary of decarbonisation pathways for the cement sector